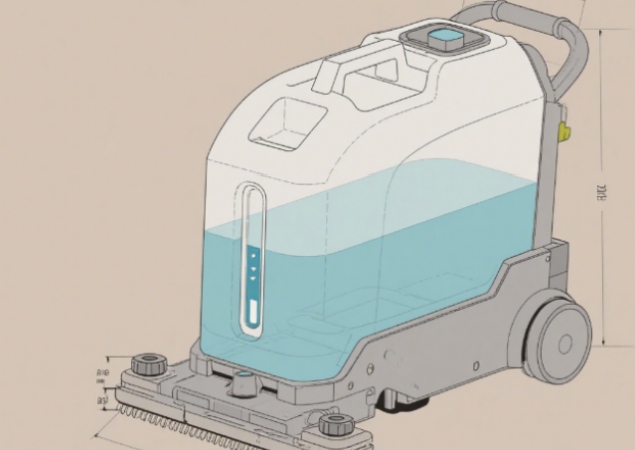

Q5 fis a high-performance walk behind floor scrubber that integrates water spraying, floor cleaning, and suction drying. It is with 10 years Germany technology. Especially suitable for use in places ranging from 500 to 2000 square meters.

Productivity Increased by 25%+

Annual Operating Costs Dropped by 20%

Durability Index Increased by 80%

Scene 1: Small Food Processing Plant (3000㎡)

Problem: High labor cost

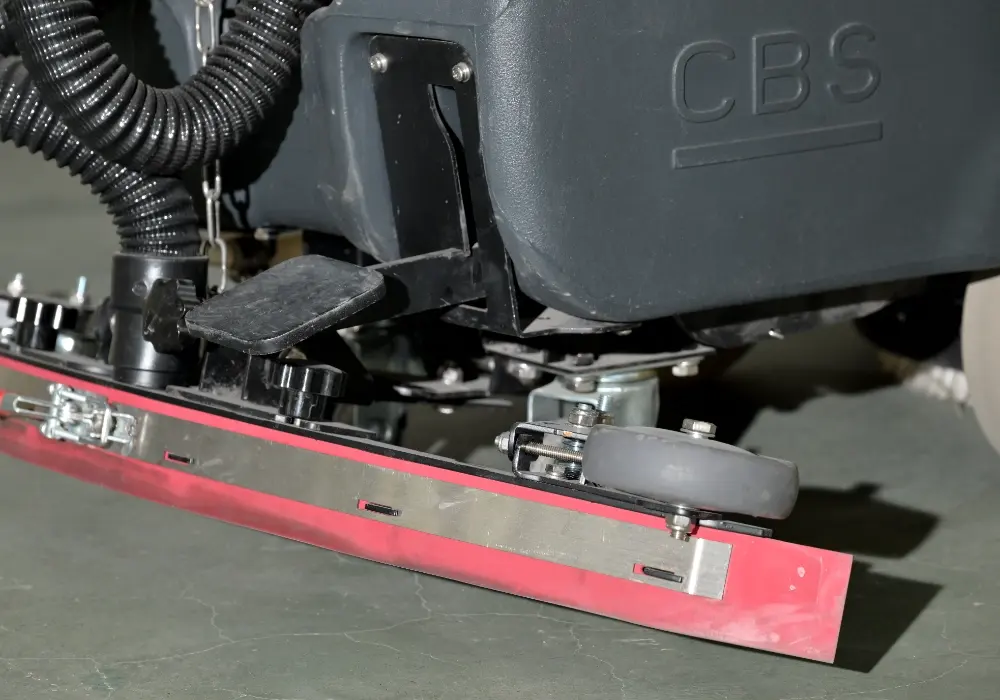

Body Design: Cleaning efficiency reaches 2100m²/h, working last up to 4 hours.

Using Q5: Cleaning coverage rate increases 75%, labor cost decreases 50%

Scene 2: Hardware Production Workshop (2000㎡)

Problem: Short service life of equipment corrosion

Body Design: Adopts a roto-molded water tank shell + sheet metal chassis design equipment

Using Q5: Cleaning efficiency increases 50%, Equipment durability upgrade 80%

Scene 3: Small Shopping Mall (3000㎡)

Problem: Narrow areas are difficult to clean

Body Design: Only 50cm cleaning width, Cleaning without obstacles

Using Q5: The pass rate in narrow areas is increased by 100%

It is with 10 years Germany technology. Especially suitable for use in places ranging from 500 to 2000 square meters.

20 Years Production Technology

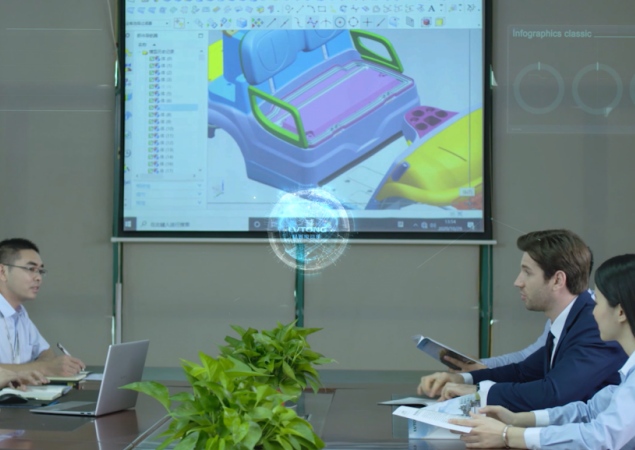

Strong Equipment R&D Capabilities

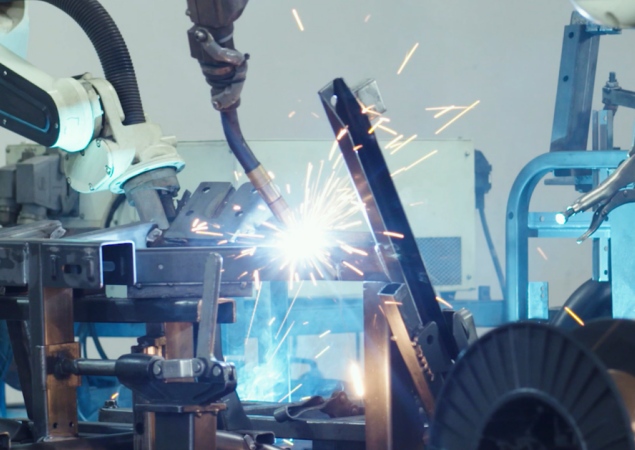

Automated Equipment Production Line

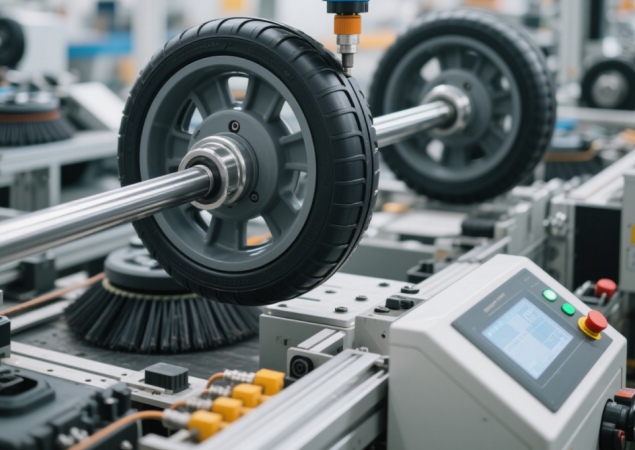

Complete Product Assembly Workshop

Strict quality inspection department

Reliable Product Patent Certificate

·lVTONG

Design

Material-Procurement

arts-Processing

Equipment-Assembly

·lVTONG

Logo-Customization

Product-Customization

Appearance-Customization

Customized-Configuration

·lVTONG

Warranty Service

Maintenance Repair

Accessories Supply

Technical Support

It depends on the model and water tank capacity. Q5 floor scrubber has a cleaning efficiency of 1980 ㎡/h and the cleaning range covering 2000 ㎡.

The water tank capacity of Q5 floor scrubber is 50L.

It is suitable for various types of floors such as cement, ceramic tiles, epoxy flooring, marble, etc.

It includes cleaning the brush disc, emptying the sewage tank, checking the battery and filter, etc.

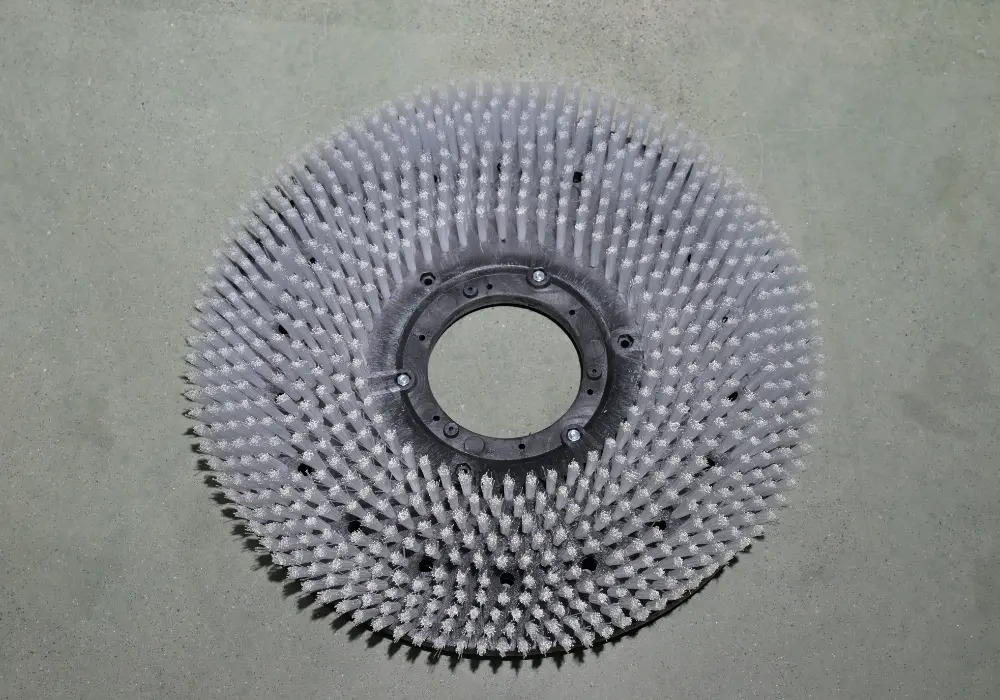

The frequency of replacing the brush disk and suction scraper depends on the usage frequency and ground conditions, usually every 3-6 months.

With 21 years of production experience, Lvtong is one of the largest floor cleaning equipment manufacturers in China.

Hexi Industrial Park,Meisha Village,Hongmei TownDongguan City,Guangdong Province