Cleaning such big warehouses efficiently, effectively, safely, and at low costs is the biggest challenge. A well-chosen ride-on scrubber can drastically cut labor, reduce water and chemical use, and deliver consistent cleaning quality across vast floors. In this guide, we break down what makes a ride-on scrubber ideal for large warehouses in 2025 — and how to pick the right one for your needs.

Why Warehouse Cleaning Requires Ride-On Scrubbers

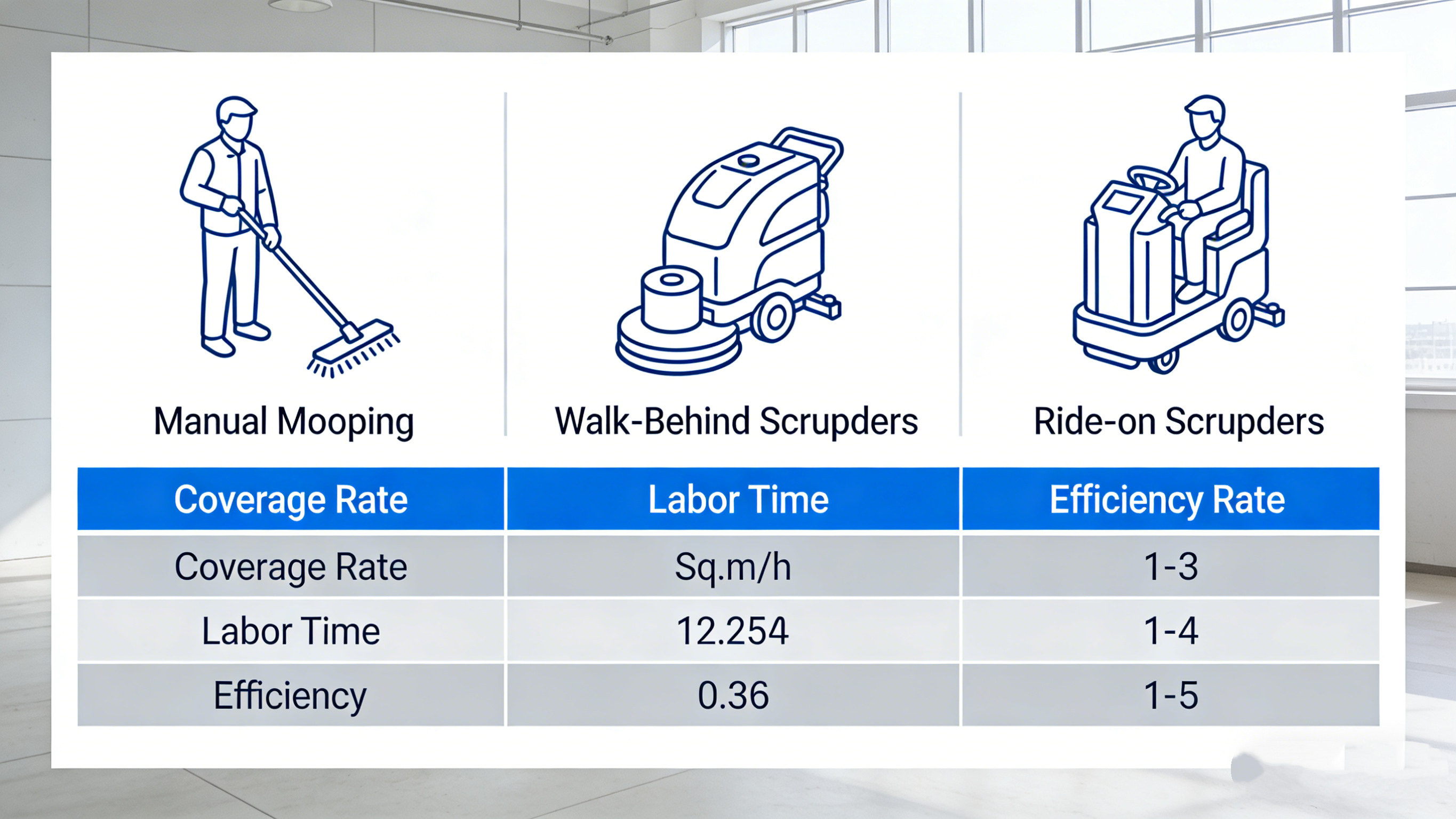

Large warehouses can span tens of thousands of square feet. Manual mopping or small push scrubbers simply can't keep up. A ride-on scrubber offers a wide cleaning path, large solution and recovery tanks, and long runtime-letting one operator cover massive floor areas in a fraction of the time.

This type of industrial warehouse floor scrubber provides consistent cleaning quality-even pressure, uniform water recovery-and quicker drying, which is critical for both safety and throughput in busy warehouse environments. For operators, the ride-on scrubbing reduces fatigue compared to manually pushing heavy machines, thereby improving productivity and lowering labor costs.

Key Criteria for Warehouse-Grade Ride-On Scrubbers

When assessing a ride-on machine for warehouse use, look at the following:

- Cleaning width & coverage rate — The wider the scrubbing path, the more floor covered per pass; this will reduce cleaning time.

- Tank capacity & runtime — Large solution and recovery tanks allow for longer runs with fewer refills, perfect for large areas.

- Flexibility in brush and squeegee system—Capability to adjust the brush pressure, applying adequate brushes that can handle concrete or rough warehouse floors.

- Durability and build quality — The heavy-duty frames and robust components have reliable motors and suction systems.

- Battery power & efficiency — Long runtime for multi-hour shifts, backed by reliable battery performance.

- Ease of operation and maintenance — Simple controls, intuitive dashboards, ease of brush and squeegee replacement, low maintenance load.

- Total cost of ownership — Total cost of ownership, not just upfront cost. Consider labor savings, water/chemical savings, and maintenance over time.

Top Ride-On Floor Scrubbers to Watch in 2025

Here are several ride-on scrubber machines from LVTONG that stand out for large warehouse use in 2025:

| Model | Cleaning Width | Tank Capacity (Solution / Recovery) | Runtime / Shift Suitability | Ideal Warehouse Size |

| LT-S860X | 860 mm | Large (e.g. 130L / 135L) | Long runtime — suitable for full-shift cleaning | Very large warehouses (20,000+ sq ft) |

| LT-S710X | Medium–Large | Mid-size tanks | Balanced runtime & maneuverability | Medium to large warehouses (10,000–25,000 sq ft) |

| LT-S560X | Medium | Moderate tanks | Good runtime for single-shift cleaning | Warehouses needing flexibility or mixed-use areas |

These industrial ride-on scrubbers combine wide cleaning paths, large-capacity tanks, long runtime, and strong build quality — all traits essential for efficient and reliable warehouse cleaning equipment.

How to Choose the Right Model for Your Warehouse

Follow these steps to select the best ride-on scrubber for your facility.

- Determine your Warehouse Size and cleaning frequency—Large facilities (for example, over 20,000 sq ft) cleanings performed more frequently gain the most value from the LT-S860X and LT-S710X wide-path, high-capacity machines.

- Evaluate floor type and condition-such as concrete, rough warehouse floors require heavy—Duty brush systems and high vacuum performance. The selected scrubber must allow for adjustable brush pressure and heavy-duty squeegees.

- Estimate shift length and downtime tolerance—For operations that require multiple shifts or have long cleaning cycles, models offering long runtimes and large water tanks are best because they minimize refilling stops.

- Consider TCO — Calculate potential savings in labor, water, and chemical usage, and maintenance over time. Often a high-end ride-on scrubber yields better ROI in 12–24 months.

- Factor in operator comfort and ease of use — Machines with ergonomic seats, easy controls, and straightforward maintenance reduce operator fatigue and maintenance downtime.

- Maintenance planning and parts availability—select a brand with available spare parts, ease of maintenance, and support - this ensures long-term reliability.

Safety and Compliance Considerations

Large warehouses are busy places - safety matters. When using ride-on scrubbers:

- Operators are trained in safe driving and turning, especially with regard to racks, pallets, and tight zones.

- Floors dry more quickly after cleaning, which reduces slip risks. Good suction and efficient squeegees come in handy.

- Warning signs, such as "Wet Floor" signs, are displayed during and immediately after cleaning.

- Above all, batteries are charged in well-ventilated areas, and electrical safety checks are followed.

- Scrubber components (tanks, hoses, electrical parts) should meet the standards to prevent leakages or component failure.

Compliant and well-maintained ride-on scrubbers will protect both people and assets, helping to meet workplace safety standards.

Conclusion and Recommendations for Action

The right ride-on scrubber can make all the difference in warehouse cleaning: faster results, lower costs, safer floors, and less labor. In 2025, some of the top models include LVTONG's LT-S860X, LT-S710X, and LT-S560X for efficient heavy-duty cleaning in a warehouse. If your facility spans thousands of square feet, and you want to cut labor costs, water use, and cleaning time, it is time to consider a ride-on scrubber. Contact LVTONG today to find a model that matches your warehouse's needs and request a demo.